- Role

- Lead UX Designer

- Company

- Smurfit Westrock

- Timeline

- 2024 | 6 months

Overview

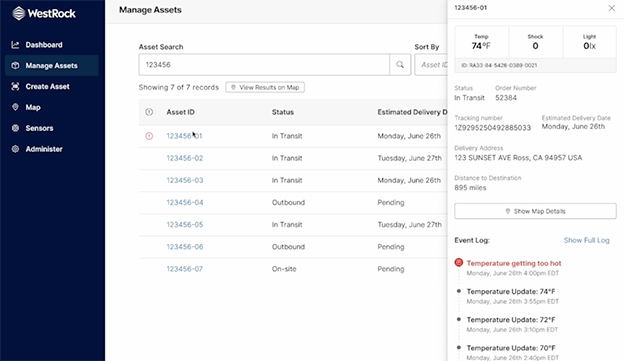

The Internet of Packaging (IoP) application is one of Smurfit Westrock’s BornDigital™ product offerings, applying internet of things technology to provide full lifecycle visibility down to the package level.

Prior to launching the IoP application, the product development team partnered with a Napa Valley winemaker who are making a name for themselves as a disruptor in the wine industry. Our pilot sought to validate the in-transit features of the app, test the feasibility of cellular hardware options for use in shipping perishable products, as well as provide new insights to the winemaker, allowing them to optimize how and when wine is shipped.

As the product’s UX lead, I was responsible for the research, synthesis and subsequent solution design that went into the application.

Go to ResultsThe Challenge

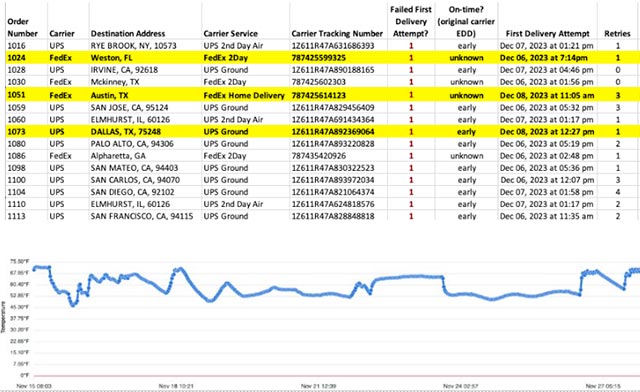

Like many perishable goods suppliers, our winemaking partner lacked visibility into their products while in transit, leading to missed opportunities to reduce risk of spoilage and shipping costs. The pilot aimed to collect quantifiable data to determine the best carrier, route and method of shipment for different regions of the country.

Wine must stay within 40-70º F (4.5-21º C) and shipments with alcohol require an adult signature at delivery. The sooner wine is delivered to the customer, the less likely it is to deviate from its optimal temperature range. In phase one, we observed that 15% of the winemaker’s shipments could not be signed for at least once, remaining in the carrier’s possession for an additional 24 hours or more, without any temperature controls. This significantly increased the risk of spoilage. Our goal was to improve the first time delivery success rate to near 100%.

Prior to and during the pilot, the IoP application had not yet been released, so pressure testing both the functionality of the app and that of the connected hardware was a key objective, as well.

The Approach

The project began with interviews of the winemaker's proprietor and staff from the distribution company responsible for order fulfillment. Based on these discussions, a process flow diagram was developed to determine optimal points for introducing IoP with minimal disruption, followed by setting up and configuring a tenancy within the IoP application for the winemaker.

Phase One

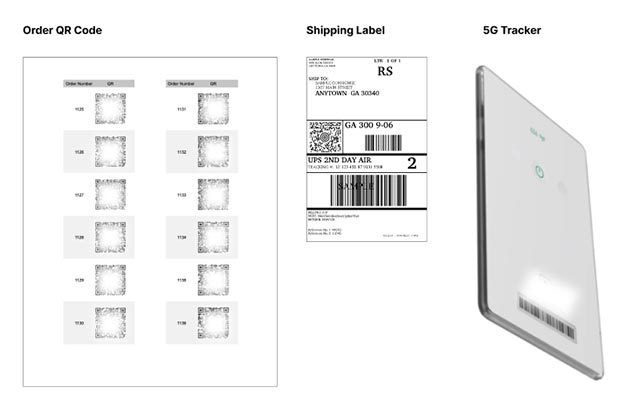

The pilot ran in two phases, collecting carrier performance data over different periods of time. Phase one established a baseline for first-time delivery success, covering 49 direct-to-consumer and two wholesale shipments, each with cellular trackers from two different manufacturers. Shipments, segmented by region, used multiple carriers via ground and air.

The product team leads were onsite at the distributor to oversee packing, enabling quick problem resolution and firsthand insights that would help inform phase two.

Post-delivery, the data revealed a first-time delivery success rate of 85%, below the USPS industry average of 92%. We found that many of these failed attempts were early deliveries, often occurring before the carrier's estimated date, suggesting a need for better communication of updated delivery times.

Phase Two

In the pilot’s second phase, an additional 21 packages were shipped. In preparation for this second set of shipments, I devised a way to encapsulate all of the pertinent order data into a QR code that would be scanned by the personnel at the wine distributor. This made for a low friction means of asset setup in the IoP application.

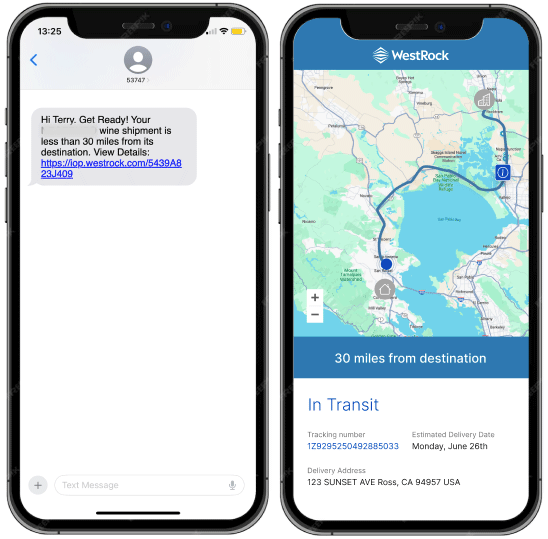

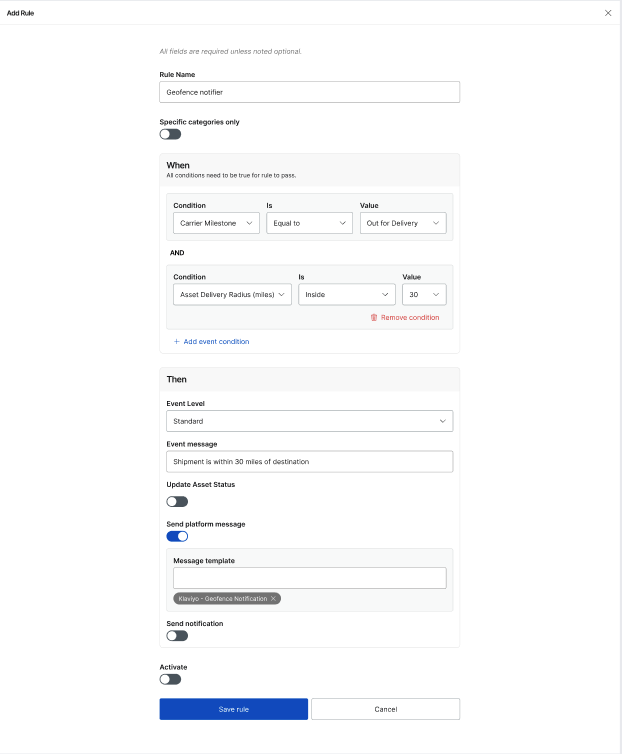

Using insights from phase one, we built a new feature for the app enabling 3rd-party integrations. This allowed messages from the IoP application to be sent to our pilot partner’s CRM. We then created an event rule in the app that combined ‘out for delivery’ messages from the carrier with a geofence trigger based on the delivery address. When the rule was activated, the customer received a text message via the CRM, notifying them when their shipment was out for delivery and nearing its destination.

As an added feature to “delight the customer,” an event rule was created to send each customer a customized email, letting them know that their wine remained at optimal conditions throughout the journey.

Results

As a result of our app-enabled proactive communications, phase 2 saw a first time delivery success of 95% and none of the shipments throughout the pilot experienced an impactful temperature deviation.

Results from the first phase showed no significant difference in temperature change between ground and 2-day air shipments. In phase two, all shipments went by ground, using a single carrier. This saved a considerable amount of money and had no ill effects on the wine.

Though the pilot’s scope limited statistical significance, the findings enabled the winemaker to plan future shipments confidently and provided valuable insights that significantly influenced the product roadmap.